Harbor Freight 36 inch Metal Brake review (unsponsored.

Registered Users 78,740 Forums 1 Topics 45,302 Replies 214 Topic Tags 4,384.

Nowadays, when people talking about press brake, they mainly refer to the hydraulic bending machine for sheet metal bending. Nowadays, when people talking about press brake, they mainly refer to the hydraulic bending machine for sheet metal bending.. After doing some homework, now I finally know why it’s been called “press brake”.

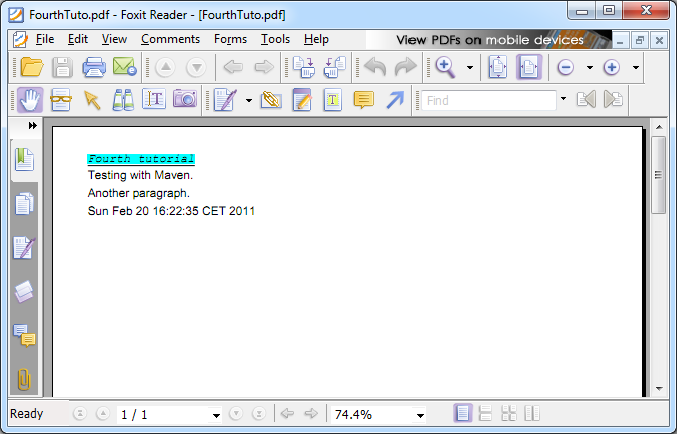

MIT 2.810 Fall 2016 Homework 5 Solutions 1 MIT 2.810 Manufacturing Processes and Systems Homework 5 Solutions Sheet Metal Forming Revised October 7, 2015 Problem 1. Springback Rank the metals in Table 2.2 (Kalpakjian, all editions) in terms of springback, listing those with the largest springback first. Answer.

Brake also has a few specialized meanings that are very rare in modern usage. In the middle ages, a brake was a toothed instrument used for separating out the fiber of flax or hemp, and modern day factories have a machine called a brake that is used for bending, folding, and flanging sheet metal.

Your focus is getting things done. Whether you're familiar with Siding Brake or not, Sunbelt experts are here when you need them for Siding Brake Rental support. No matter the issue, a solution is a phone call away to your local Sunbelt support team. High Quality Performance. Sunbelt Rentals equipment is maintained to ensure it's ready for your.

This sheet metal brake can bend boxes or pans to almost any depth since it doesn’t rely on conventional finger depths. Runs on 220-volt single-phase power and will work at virtually any site.; 48” (4-foot) length with a maximum capacity of 16 gauge mild steel.; The breakthrough open-ended design allows you to create enclosed ducts and shapes impossible to make with a traditional box and.

Re: Latest Project - Sheet Metal Brake I put one together about ten years ago for a one time on site ,wish I had thought about the spring and bolt for the for the top plate ,I use a side hinge and C clamps also I forgot to knife edge the leading edge so every thing bent had the radius of the iron.

Sheet Metal Design Tips for Bending. So, I talked to our experienced sales engineer who knows his bit about sheet metal bending. He lit up and decided to make the fullest of the opportunity to share his insights on sheet metal bending. Thus, he brought out a list of common mistakes and the solutions to avoid them. Minimum Flange Length.

Understanding the costs of a sheet metal part will help you evaluate the choices each supplier is making to provide their price. First, let’s take a look at some of the key components of a sheet metal fabrication quote. Typically they include four important areas: materials, labor, services and overhead. You.

Sheetmetalworld.com: fabrication news, sheet metal vendors database, engineering events and exhibitions, sheet metal tutorials and much more. Exhibitions View upcoming sheet metal manufacturing trade show events, or submit your own.

Measuring and marking out spiiner on sheet metal. Safe and correct use of Tin Snips. Safe and correct use of Guillotine - to cut out blanks for metal spinner. Safe and correct use of Finger Break - bend safety edges of metal spinner. Click this link to download the PAN BRAKE SOPS. Practical Sessions.

Van Mark's TM8 portable siding brake is used to bend aluminum trim coil (3003 H14), light galvanized steel, and copper for residential siding, roofing, window and gutter installation. Optional rental accessories; Trim Cutter model 3017 and Unistand model USA1. The TM8 is lightweight and portable and very easy to operate and maintain.

Metal Bending Tools Metal Tool Box Metal Working Tools Metal Projects Metal Crafts How To Make Metal Sheet Metal Work Welding Table Welding Art How to Make a Sheet Metal Box: 1) first you want to make an expanded template for your box out of cardboard, paper, etc. ( a flat version of your box.